Along with the transition from shellac records to vinyl records in the 50s, came the technology of producing stampers for pressing vinyl records from lacquer substrates. Lacquers are aluminium discs coated with a nitrocellulose layer into which a sound groove (more info in the Mastering section) is cut. By the mid-eighties, when DMM technology was still quite young, it was the only available professional technology implemented and with advancements, is still being used today.

GZ Media accepts already cut customer supplied lacquers as substrates for the production of vinyl records as well as other products from the electroforming processes - nickel fathers, mothers and unformed stampers. Please note, however, that GZ will not be held liable for any defects already present on the supplied materials on the occasion of a claim/complaint. The quality and condition of the material supplied for the manufacturing process will ultimately influence the quality of the final result and will be taken into account during the resolution of any claims.

Silvering process

After cutting the audio grooves on the lacquer substrate in the mastering studio, it is necessary to send the lacquer for further processing as soon as possible to avoid the loss of high frequencies in the grooves due to the delicate characteristics of the lacquer layer as well as damaging environm

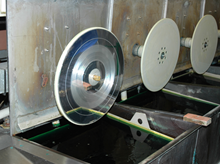

ental effects. For subsequent electroforming reproduction, it is necessary that the layer with the grooves is electrically conductive and able to act as a cathode. The lacquer is put in a special container and thoroughly rinsed with demineralized water and is then degreased in a dedicated bath and chemically activated. Finally, while still in the special container, it is sprayed with a solution of silver nitrate, which reacts with the activated surface of the lacquer and forms a thin layer of conductive silver over the surface. The next processes can begin after rinsing the just silvered lacquer. In most cases, a triple-step electroforming process is involved.

Father (original) production

The silvered lacquer is immersed as a cathode in an electroforming bath consisting of a solution of nickel salt and other ingredients. An electric current flows throughout the bath from the nickel anode to the cathode and causes a metallic nickel layer to form over the surface. This is a two-step process: first, the nickel is formed on the surface at a lower current in order to gradually create

The silvered lacquer is immersed as a cathode in an electroforming bath consisting of a solution of nickel salt and other ingredients. An electric current flows throughout the bath from the nickel anode to the cathode and causes a metallic nickel layer to form over the surface. This is a two-step process: first, the nickel is formed on the surface at a lower current in order to gradually create the initial layer of nickel coverage on the silver and secondly, up to the required thickness with a stronger current. A mirror image (negative) record called a "father" or an "original” is produced after the nickel layer is separated from the lacquer. Due to the silver layer damaging the grooves on the original lacquer after separation, normally only 1 father can be produced per lacquer. After the separation of the nickel layer from the lacquer, the original lacquer is thus rendered useless. The nickel father can now be used for making other production components.

the initial layer of nickel coverage on the silver and secondly, up to the required thickness with a stronger current. A mirror image (negative) record called a "father" or an "original” is produced after the nickel layer is separated from the lacquer. Due to the silver layer damaging the grooves on the original lacquer after separation, normally only 1 father can be produced per lacquer. After the separation of the nickel layer from the lacquer, the original lacquer is thus rendered useless. The nickel father can now be used for making other production components.

Mother (positive) production

The result of the next electroforming process is called a "mother" or a "positive". After the nickel father is cleaned, deslivered, passivated and a dividing layer is created, the father is immersed as a cathode into another nickel bath, which differs according to some parameters from the previous bath. Passing an electric current through the bath creates a second nickel layer, which is now a mirror image of the father. After mechanical separation from the father, a copy (positive) of the original recording is created. The mother therefore carries a copy of the original sound grooves and is able to be listened to and visually inspected to assure that the previous processes were completed correctly. It is possible to make several mothers from one father.

The result of the next electroforming process is called a "mother" or a "positive". After the nickel father is cleaned, deslivered, passivated and a dividing layer is created, the father is immersed as a cathode into another nickel bath, which differs according to some parameters from the previous bath. Passing an electric current through the bath creates a second nickel layer, which is now a mirror image of the father. After mechanical separation from the father, a copy (positive) of the original recording is created. The mother therefore carries a copy of the original sound grooves and is able to be listened to and visually inspected to assure that the previous processes were completed correctly. It is possible to make several mothers from one father.

When the mother is OK, the matrix number is engraved into the area between the run-out grooves. This number is the basic identification number which helps us identify which plate and label belong to which side of the record as well as identifying the production in our warehouse and internal database. The customer can also request to engrave other data such as a catalogue number, company name, small message, etc. into the run-out area. These engravings are transferred to the stampers and will be visible on all pressed records.

When the mother is OK, the matrix number is engraved into the area between the run-out grooves. This number is the basic identification number which helps us identify which plate and label belong to which side of the record as well as identifying the production in our warehouse and internal database. The customer can also request to engrave other data such as a catalogue number, company name, small message, etc. into the run-out area. These engravings are transferred to the stampers and will be visible on all pressed records.

Stamper (matrix) production

The engraved nickel mother is then subjected to a thorough process of washing, degreasing, passivation and then a dividing layer is created. The mother is immersed as a cathode in a 3rd electroforming bath consisting of a solution of nickel salt and other ingredients, with again, slightly different parameters from the previous bath. An electric current is passed through the bath to gradually form the required layer of metallic nickel on the surface of the mother. After mechanical separation of the acquired nickel layer from the mother, we then obtain another mirror image (negative) of the record, now yielding an unformed stamper. This stamper can then be used to press 500-1000 vinyl records. It is possible to produce several stampers from 1 mother repeatedly after several years, which is advantageous both for higher quantity pressings as well as for reissues.

The engraved nickel mother is then subjected to a thorough process of washing, degreasing, passivation and then a dividing layer is created. The mother is immersed as a cathode in a 3rd electroforming bath consisting of a solution of nickel salt and other ingredients, with again, slightly different parameters from the previous bath. An electric current is passed through the bath to gradually form the required layer of metallic nickel on the surface of the mother. After mechanical separation of the acquired nickel layer from the mother, we then obtain another mirror image (negative) of the record, now yielding an unformed stamper. This stamper can then be used to press 500-1000 vinyl records. It is possible to produce several stampers from 1 mother repeatedly after several years, which is advantageous both for higher quantity pressings as well as for reissues.