This concept involves checking of the supplied audio master, making minor changes (if necessary) to the final version to ensure that it is suitable for the cutting and production of vinyl records and the final transcribing of the prepared audio onto a physical carrier by cutting the grooves into the master plates via DMM, or, in special cases, lacquer technology.

When we receive an audio master, we consider the master to be artistically finished and ready for vinyl production – meaning that their dynamics and range of frequencies have already been approved by the customer. We expect that the customer wants the end product to sound the same as the supplied data. Our objective is to achieve the truest possible transfer of the supplied audio material to vinyl through the available technologies.

In the case that the customer has special requirements, we only provide basic modifications of the sensitive data supplied in order to achieve and conform to specific characteristics and parameters of vinyl records while attempting to reduce the risk of distortion and maintaining the widest range of audible frequencies.

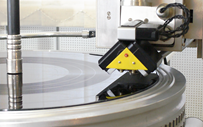

DMM technology

Direct Metal Mastering (DMM) is the youngest of the technologies used in the production of gramophone records. DMM technology was developed in the ‘80s by the company Teldec and Neumann. Since 2010, the GZ further developed and improved this cutting technology. GZ is the only factory in the world which is continuously commercially operating 3 upgraded DMM cutting lathes. The groove is cut by a diamond stylus into a copper layer electroplated on a non-magnetic steel sheet. Stampers are then made directly from the mastered copper plates by a single step electroforming process. The advantage of DMM is a better transmission of high frequencies, lower noise, reduced print-through sounds (pre-echo) between adjacent grooves and a more efficient use of space on the record surface, which allows you to press even longer recordings on to vinyl. DMM technology is suitable for both standard LPs, as well as high-quality audiophile 45rpm recordings.

More

Lacquer technology

Cutting into lacquer is a traditional mechanical recording technology which has been used since '50s. The groove is cut by a heated sapphire stylus directly into the soft outer layer of an aluminium plate coated with a layer of nitrocellulose varnish. Subsequent production of metal parts typically requires a 3 step galvanic process which is complicated and expensive. The surface of the lacquer is very vulnerable, so it is therefore recommended to process the lacquers as soon as possible after they have been cut. Lacquer technology allows a wider groove cut and a greater depth, but at the cost of more overall usage of the vinyl surface, thus reducing the available playing time and limiting the recording level (thus, total volume) of longer recordings. The disadvantage is also more noise, increased print-through sounds (pre-echo) between adjacent grooves and worse transmission of high frequencies, especially closer to centre hole. The advantage is the possibility of a slightly higher recording level for shorter titles, thanks to the softer layers of varnish. It may be more appropriate for DJ and dance maxi-singles, for example.

More

New mastering system

Mechanical recording technology was originally optimized for recording human voices and acoustic instruments during the initial stages of its development. With the emergence of new musical genres and the popularity of electronically and digitally processed and produced music, it is increasingly common to come across recordings which are very difficult and time consuming concerning the determination of the most appropriate parameters for cutting.

Engineers and technicians at GZ therefore developed worldwide unique software for analyzing audio recordings and cutting simulation using virtual grooves in the computer's memory. In acoustically separate studios, our specialists can carefully and efficiently prepare audio data and set the optimal parameters for recording, while other operators in transcribing studios are fully dedicated to cutting lathes which are controlled using the same software.

Although DMM is GZ’s primarily implemented cutting technology, there are occasionally some recordings which would benefit more through the lacquer process. Our new software is able to alert us if this is the case.

More